PEEK材料的机器人传感器介绍

PEEK(聚醚醚酮)是一种高性能特种工程塑料,具备耐高温(长期使用温度约 240℃)、耐化学腐蚀、高强度、轻量化、低摩擦系数及优异的电气绝缘性等特性,这些优势使其成为机器人传感器关键部件的理想材料,能解决传统金属或普通塑料传感器在精度、稳定性、环境适应性上的短板。

一、

核心应用类型及特点

PEEK 材料主要通过制造传感器的

核心结构件或

功能基底发挥作用,常见应用类型如下:

1.六维力 / 力矩传感器

应用部位:传感器的 "弹性体"(力信号感知核心部件)。

核心价值:传统弹性体多采用铝合金,而 PEEK 的弹性模量与密度比更优 —— 在保证结构强度的同时,大幅降低弹性体质量,减少机器人运动时的惯性干扰,提升力值测量精度(可达 ±0.1% FS)和动态响应速度(响应时间<1ms)。

典型场景:工业机器人装配(如精密螺丝锁付力控制)、协作机器人人机交互(如碰撞力感知)、医疗机器人手术力反馈(如骨科机器人骨面打磨力监测)。

2.触觉 / 应变传感器

应用部位:传感器的柔性基底或电极载体。

核心价值:PEEK 具备一定柔性与耐疲劳性,可加工成薄型或异形结构,适配机器人手指、抓手等曲面 / 柔性接触场景;同时其电气绝缘性可避免信号干扰,保障触觉(如压力、纹理识别)或应变(如关节形变)数据的稳定性。

典型场景:服务机器人抓取易碎品(如玻璃、水果)的压力感知、工业机器人柔性装配的贴合度应变监测。

3.耐腐蚀环境专用传感器

应用部位:传感器的外壳、探头保护套或接触部件。

核心价值:PEEK 对酸碱溶液、有机溶剂及高温蒸汽(如食品行业的 CIP 清洗)耐受性极强,远优于不锈钢或普通塑料,可保护传感器内部元件不受腐蚀,延长使用寿命。

典型场景:食品 / 医药机器人的液位 / 浓度传感器(如酱料罐液位监测)、化工机器人的环境参数传感器(如腐蚀性气体检测探头保护)。

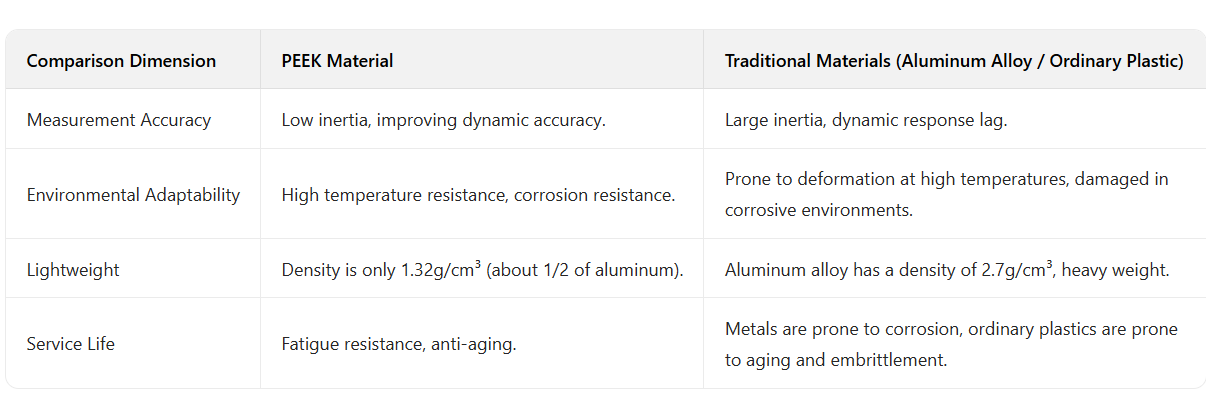

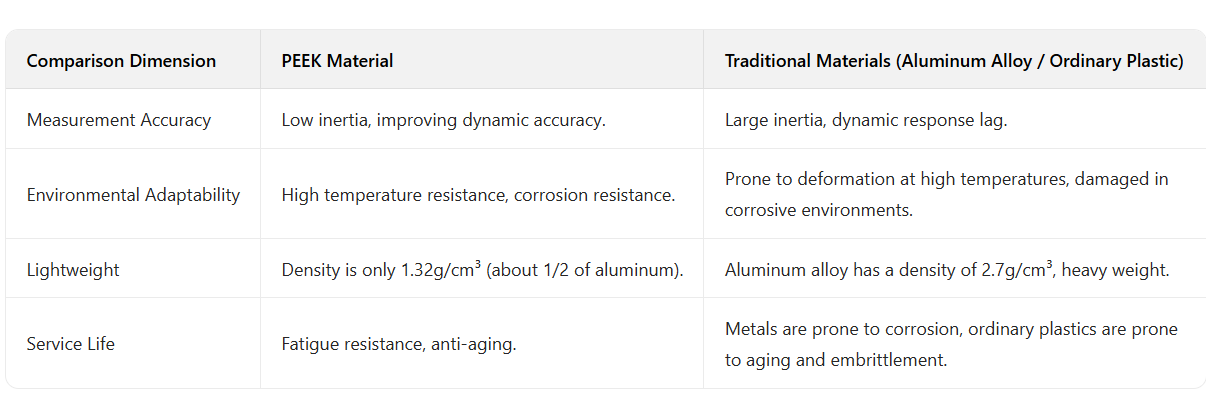

二、相比传统材料的核心优势

|

对比维度 |

PEEK 材料 |

传统材料(铝合金 / 普通塑料) |

|

测量精度 |

低惯性,提升动态精度 |

惯性大,动态响应滞后 |

|

环境适应性 |

耐高温、耐腐蚀 |

高温易变形,腐蚀环境易损坏 |

|

轻量化 |

密度仅 1.32g/cm³(约为铝的 1/2) |

铝合金密度 2.7g/cm³,重量大 |

|

使用寿命 |

耐疲劳、抗老化 |

金属易锈蚀,普通塑料易老化脆 |

三、典型应用领域

工业机器人:装配力控制、打磨力反馈、抓取压力监测;

医疗机器人:手术器械力感知(如腹腔镜操作力反馈)、康复机器人的关节应变监测;

特种机器人:食品 / 化工领域的耐腐蚀环境传感器、高温工况(如汽车焊接)的温度 / 力传感器。

Introduction to PEEK Material Robot Sensors

PEEK (Polyether Ether Ketone) is a high-performance specialty engineering plastic with properties such as high temperature resistance (long-term service temperature around 240°C), chemical corrosion resistance, high strength, lightweight, low friction coefficient, and excellent electrical insulation. These advantages make it an ideal material for key components of robot sensors, addressing the shortcomings of traditional metal or ordinary plastic sensors in terms of precision, stability, and environmental adaptability.

I. Core Application Types and Characteristics

PEEK material mainly functions by manufacturing the core structural components or functional substrates of sensors. Common application types are as follows:

1. Six-Dimensional Force/Torque Sensors

Application Part: The "elastic body" (the core component for force signal perception) of the sensor.

Core Value: Traditional elastic bodies are mostly made of aluminum alloy, while PEEK has a better ratio of elastic modulus to density - ensuring structural strength while significantly reducing the mass of the elastic body, minimizing inertial interference during robot movement, and improving force measurement accuracy (up to ±0.1% FS) and dynamic response speed (response time < 1ms).

Typical Scenarios: Industrial robot assembly (such as precise screw tightening force control), collaborative robot human-machine interaction (such as collision force perception), medical robot surgical force feedback (such as bone surface grinding force monitoring in orthopedic robots).

2. Tactile/Strain Sensors

Application Part: The flexible substrate or electrode carrier of the sensor.

Core Value: PEEK has certain flexibility and fatigue resistance, allowing it to be processed into thin or irregular shapes, suitable for curved or flexible contact scenarios such as robot fingers and grippers; at the same time, its electrical insulation can prevent signal interference, ensuring the stability of tactile (such as pressure, texture recognition) or strain (such as joint deformation) data.

Typical Scenarios: Pressure perception in service robots when grasping fragile items (such as glass, fruits), strain monitoring for the fit in industrial robot flexible assembly.

3. Specialized Sensors for Corrosive Environments

Application Part: The housing, probe protection sleeve, or contact components of the sensor.

Core Value: PEEK has extremely strong resistance to acids, alkalis, organic solvents, and high-temperature steam (such as CIP cleaning in the food industry), far superior to stainless steel or ordinary plastics, protecting the internal components of the sensor from corrosion and extending its service life.

Typical Scenarios: Liquid level/concentration sensors in food/medical robots (such as monitoring the liquid level in sauce tanks), environmental parameter sensors in chemical robots (such as protecting corrosive gas detection probes).

II. Core Advantages over Traditional Materials

III. Typical Application Fields

Industrial robots: Assembly force control, grinding force feedback, grasping pressure monitoring;

Medical robots: Force perception of surgical instruments (such as force feedback in laparoscopic operations), joint strain monitoring of rehabilitation robots;

Special robots: Corrosion-resistant environment sensors in food/chemical fields, temperature/force sensors in high-temperature conditions (such as automotive welding).

- 大连路阳科技开发有限公司

- 全国热线:0411-87641009

- 电子邮箱:

- 地址:辽宁省大连市经济技术开发区保灵街1-3号

全国服务热线

全国服务热线